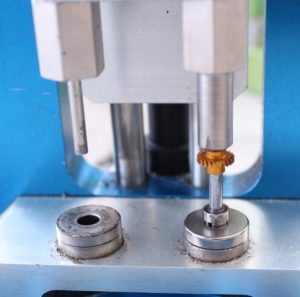

Turbine Components

Bearings

Impeller

Spindle

O-Rings

Is it difficult to rebuild a handpiece?

Rebuilding a dental handpiece is actually simple. Below, find the steeps needed to complete a dental handpiece rebuild:

How much time does it take to rebuild a handpiece?

The process of rebuilding a dental handpiece can take between five and 30 minutes. The process will be quicker as a person becomes comfortable with the turbine’s components, the direction the components go onto the spindle, and the function of the dental press.

How much money does rebuilding a handpiece save?

How long will a handpiece last between each rebuild?

Under standard use and care, handpiece repairs last between nine and 15 months. A turbine is only as good as its weakest component. If a dentist fails to change o-rings or bearings with each repair, the turbine’s lifespan will be cut down significantly. While it may save money in the short-term, it can increase the handpiece’s long-term repair costs. Professional handpiece repair companies like True Spin Dental can save dentists money in the long run due to proper component replacement every time. Dentists can save money by regularly fixing handpieces instead of buying new handpieces. If you’re ready to start saving, please contact us today!